তার EDM মেশিন কীভাবে কাজ করে: স্ফুলিঙ্গ ক্ষয় এবং মূল উপাদানগুলির নীতি। তার EDM কী এবং এটি কীভাবে কাজ করে: স্ফুলিঙ্গ ক্ষয়ের মৌলিক বিষয়। তার EDM মেশিনগুলি একটি পাতলা তামার তার এবং পরিবাহী ধাতুর মধ্যে নিয়ন্ত্রিত বৈদ্যুতিক স্ফুলিঙ্গ তৈরি করে ধাতু কাটে...

আরও দেখুন

EDM মেশিন এবং অণু-মেশিনিংয়ে এর ভূমিকা বোঝা। EDM মেশিন কী? বৈদ্যুতিক ডিসচার্জ মেশিনিংয়ের মৌলিক বিষয়। EDM মেশিন, যার পূর্ণরূপ ইলেকট্রিক্যাল ডিসচার্জ মেশিনিং, একটি ইলেকট্রোড এবং কাজের টুকরোর মধ্যে নিয়ন্ত্রিত বৈদ্যুতিক স্ফুলিঙ্গ প্রেরণ করে কাজ করে...

আরও দেখুন

টিউব মিল উৎপাদনে বৈশ্বিক মানগুলির সাথে সামঞ্জস্য (API, ASTM, ISO)। ঘটনা: কঠোর পরিবেশে আদর্শীকৃত ইস্পাতের পাইপের চাহিদা বৃদ্ধি। পন্... অনুসারে গত বছর তেল ও গ্যাস শিল্পে পাইপলাইনের ব্যর্থতার কারণে প্রায় 740 মিলিয়ন ডলার ক্ষতি হয়েছে

আরও দেখুন

জলজেট কাটিং মেশিনের পরিবেশগত এবং স্বাস্থ্যগত সুবিধা: তাপ-প্রভাবিত অঞ্চল (HAZ) এর অনুপস্থিতি এবং শীতল কাটিং-এর সুবিধা। জলজেট কাটিং একটি শীতল কাটিং পদ্ধতির মাধ্যমে কাজ করে যা তাপজনিত বিকৃতির সমস্যা দূর করে, ফলে কাঠামোগত অখণ্ডতা অক্ষুণ্ণ থাকে...

আরও দেখুন

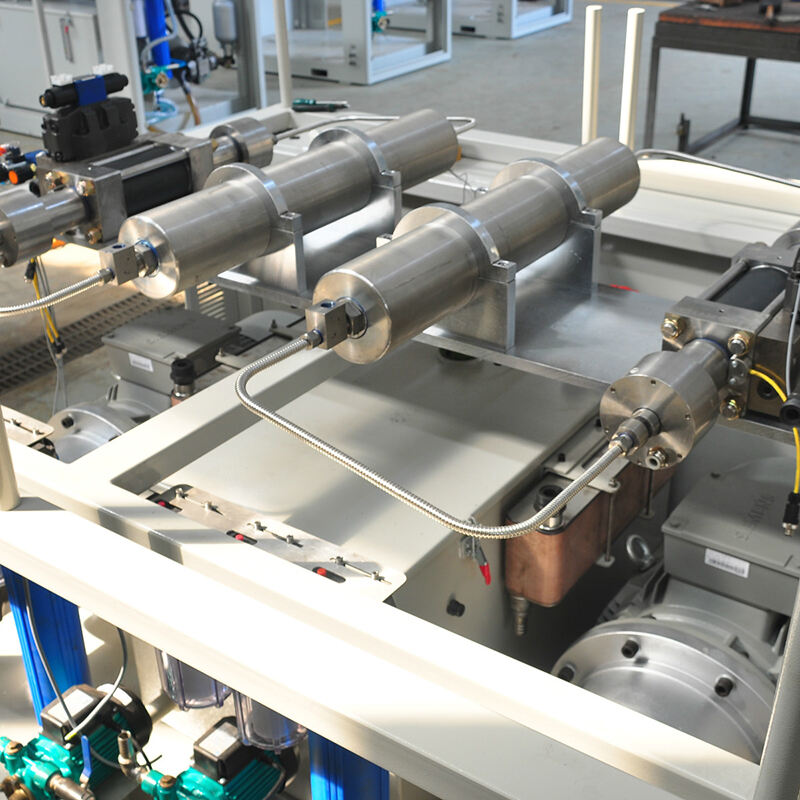

EDM ড্রিলিং মেশিন কীভাবে নির্ভুলতা এবং নিয়ন্ত্রণকে পুনর্গঠন করে? EDM ড্রিলিং মেশিন কী এবং এটি কীভাবে কাজ করে? EDM ড্রিলিং মেশিন ঘূর্ণায়মান ইলেকট্রোড এবং বিশেষ তরলে স্থাপিত ধাতব অংশগুলির মধ্যে ক্ষুদ্র বৈদ্যুতিক স্ফুলিঙ্গ তৈরি করে কাজ করে...

আরও দেখুন

অ-তাপীয় প্রক্রিয়া হিসাবে জলজেট কাটিং কীভাবে কাজ করে জলজেট কাটিং কী এবং কীভাবে এটি অ-তাপীয় প্রক্রিয়া হিসাবে কাজ করে জলজেট কাটিং অত্যন্ত উচ্চ চাপে (প্রায় 90,000 psi) জল উপকরণের মধ্য দিয়ে ছুড়ে দেওয়ার মাধ্যমে কাজ করে, যা উপকরণে তাপ সৃষ্টি না করেই কাটিং করে...

আরও দেখুন

গহনা উৎপাদনের বিবর্তন: EDM মেশিন কীভাবে ডিজিটাল নির্ভুলতা প্রদান করে ঐতিহ্যবাহী শিল্প থেকে EDM সহ ডিজিটাল মেশিনিংয়ে রূপান্তর আগেকার দিনগুলিতে, মূলত ছুরি এবং মোমের মডেলের মতো মৌলিক যন্ত্রপাতি ব্যবহার করে হাতে কাজ করতেন, যার অর্থ হল...

আরও দেখুন

দৈর্ঘ্য অনুযায়ী কাটার লাইন স্বয়ংক্রিয়করণ এবং নিয়ন্ত্রণ ব্যবস্থার বিবর্তন যান্ত্রিক রিলে থেকে PLC এবং HMI পর্যন্ত: দৈর্ঘ্য অনুযায়ী কাটার লাইন নিয়ন্ত্রণে প্রযুক্তিগত লাফ দৈর্ঘ্য অনুযায়ী উৎপাদন লাইনগুলি আর মৌলিক যান্ত্রিক নিয়ন্ত্রণের উপর নির্ভর করে না বরং এগুলি...

আরও দেখুন

ইডিএম মেশিন প্রযুক্তি কীভাবে কাজ করে: স্ফুলিঙ্গ ক্ষয়ীভবনের নীতি বৈদ্যুতিক ডিসচার্জ মেশিনিং (ইডিএম) এর মৌলিক বিষয় এবং নীতি ইডিএম, যার অর্থ বৈদ্যুতিক ডিসচার্জ মেশিনিং, এটি কাটিং টুলের পরিবর্তে নিয়ন্ত্রিত বৈদ্যুতিক স্ফুলিঙ্গের মাধ্যমে উপাদান সরিয়ে নেয়...

আরও দেখুন

ইডিএম ডাই সিঙ্কিং মেশিনগুলি কীভাবে কাজ করে: নির্ভুল স্ফুলিঙ্গ ক্ষয়ীভবনের নীতি সিঙ্কার ইডিএম (ডাই-সিঙ্ক ইডিএম) প্রক্রিয়া এবং কাজের নীতি ইডিএম ডাই সিঙ্কিং মেশিনগুলি নিয়ন্ত্রিত বৈদ্যুতিক ডিসচার্জের মাধ্যমে পরিবাহী উপকরণগুলির আকৃতি পরিবর্তন করে। এটি ঘটে যখন...

আরও দেখুন

পাইপ তৈরির মেশিনগুলি কীভাবে কাঁচামালকে সম্পূর্ণ পাইপে রূপান্তরিত করে আজকের পাইপ উৎপাদন সরঞ্জাম স্বয়ংক্রিয় এক্সট্রুশন পদ্ধতি ব্যবহার করে কাঁচা প্লাস্টিক বা ধাতুকে সঠিকভাবে আকৃতি দেওয়াকে অনেক সহজ করে তোলে। এই প্রক্রিয়া তাপ প্রয়োগ করে শুরু হয়...

আরও দেখুন

ইডিএম তার কাটার মেশিন কীভাবে কাজ করে: বৈদ্যুতিক ডিসচার্জ মেশিনিংয়ের পিছনে বিজ্ঞান। ইডিএম তার কাটার মেশিনগুলি তাপীয় ক্ষয়ের মাধ্যমে উপাদান অপসারণের জন্য একটি পাতলা তার ইলেকট্রোড এবং একটি পরিবাহী কাজের টুকরোর মধ্যে নিয়ন্ত্রিত বৈদ্যুতিক স্ফুলিঙ্গ ব্যবহার করে। থ...

আরও দেখুন