Izimpendulo eziphambene neyohlunga weNozzle

Kunezimo ezimbili eziphambene nokuthi nozzle iywe – ukweywa kusuka emfuleni onenmineral (>100ppm total dissolved solids) nezincu zoqeqesho – okuguqula ububanzi be-nozzle, nokungcola kompela wojwayezo. Ukuculula kwenzeka uma isiqalo se-garnet esiphelile noma izinkunzi esingena kuzindlela zokudlulisela. Uma le ndawo zombili ziphetgetherwa, kungenxa yale nto kuhlanganisa ukujwa okungcono nokuthambiswa kwamachininga futhi kungaba ngu-70% futhi kungaphansi kokuphila (20024 Flow Science). Ukubheki ngokore kanye ngemuva kwengequ 50 yamaxesha egcinweyo kunikeza amaphoyinti okuthola ukuthambiswa ngokushesha.

Izindlela Zokucula Ezilandelayo Ukususa Izicelo zeAbrasive

Vikela ukwehliswa okungasekho ngokwenza uhlelo lokuqina:

- Hlameza amandla e-waterjet ngemvula yasile 5 imizuzu

- Sebenzisa ukucula kwesifudogalombili xa kuculwa izinkampani zokuxhumana

- Linganisa izinkaweni zemiphefumulo ngokusebenzisa izindleko ezine tip ye-nylon kuphela

Vikela ubude be-pH bemandla phakathi kwe-6-8, nokuba amandla angaphansi noma angaphezulu ayongezela ukugaya. Ukucatsa kwegesi ikwazi ukugcina ama-97% wama-particulates asingaphansi kwe-50-micron, kakhulu ukuhlongisa isikhathi se-nozzle xa sisebenzisa ngaphambili.

Ukulinganisa izilingo ne-analisi yokunciphisa izindleko

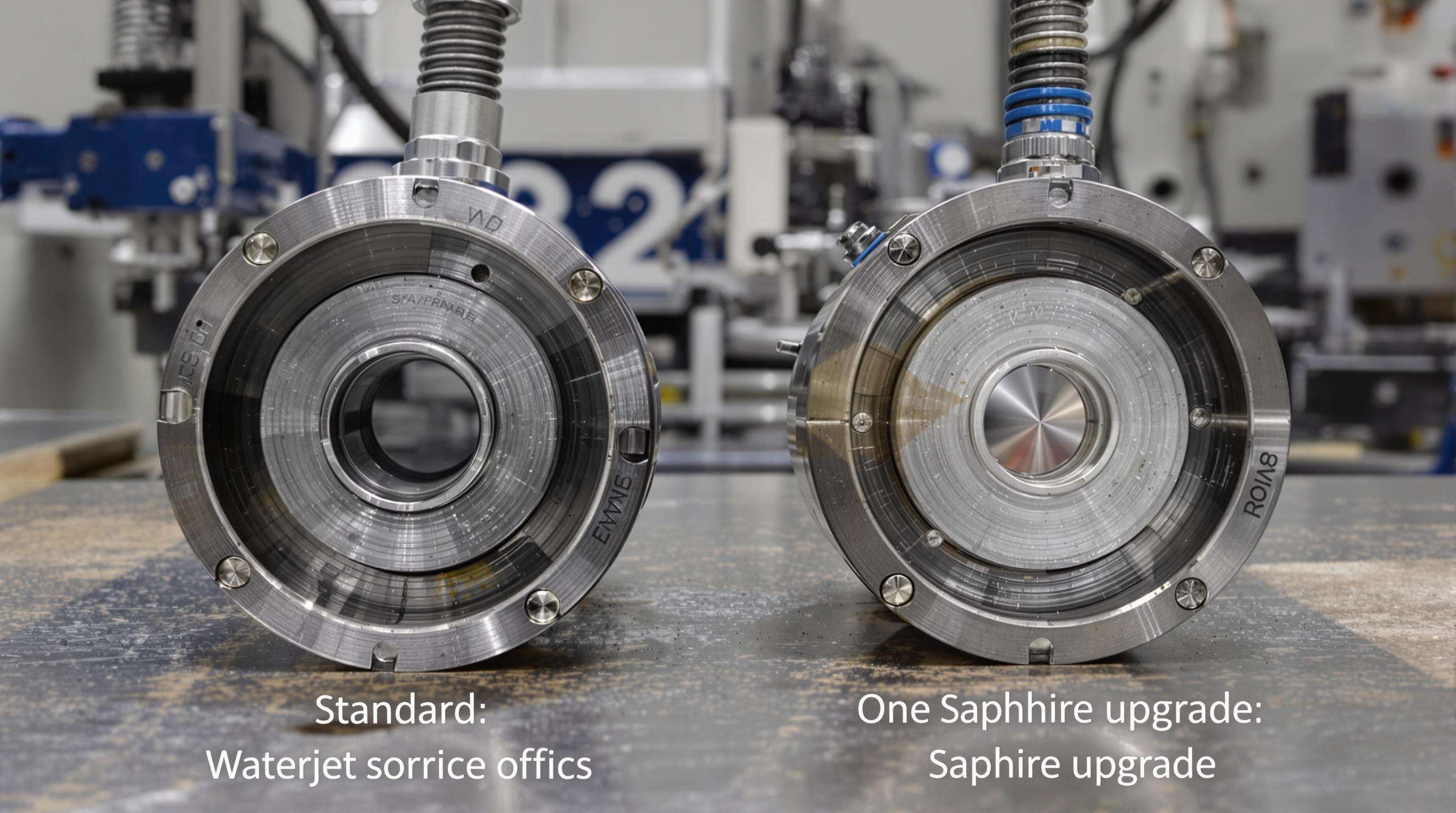

| Ifakti | Isilayide Esijwayelekile | Ukuthuleka Lwe-Sapphire |

|---|---|---|

| Isikhathi Esibonakalayo | 100 iintsuku | 400 amacemu |

| Ukugcina Isantya Sokukhupha | -55%/150 amacemu | -12%/400 amacemu |

| Imipumela Yekhomiso Emyeni | Isigaba Esikhulu | ~$5,300* |

*Lokhu kubekwe kuleli qembu elingu-24/5 kunoma izindleko zokungasebenzi (Umphakathi weNkampani yemijet yaMali 2023). Yenza kabusha i-calibration ongu-2 amacemu emuva kokubuya ukuvakashela—izis adjustment ezingelwa kwenza amaphutha ngama-18% wokudonsa. Landele ukungcola ngokulingana neendidi zomkhiqizo ukuze ukunciphise izikhathi zokubuyisa (ngokwesibonelo 80-120 amacemu okukhupha ukuze kube nephawula).

Ukugcina Imijet Yebhombu kwemijet Sistimu Yokukhupha

Izilungelelo Zokugcinwa Kwamandla: Ukuvavanya nokulayisha

Ukuphazinywa okungcono kuholela esikhundleni kanye nokuthiwa kuvulekile. Vavanya ukuphazimba xa izincazelo ziphumela, uvumele ukuchanya ±5% kuspecification. Ngenkathi kusebenza, sebenzisa isoftweya yokuhlola ukuze ulandelane nezithunywa zokugcina. Ukwenza futhi ngokwesibini kuvikela ukuthambuka.

Ukuthola Overstroking Ngokusebenza Datha Yomthombo

Overstroking iyaphakama amabheiringi nezindanda zokukhanyisa, ebonakala ngokuphezulu kwezibuko (le>68°C) nezintaba ezinhle zokugcina. Hlwanani idatha yosebenzo ukubona ukungaqondisiwe kwezinto embindini. Yenza ukuphazimba kwamanzi kahle ukuze uhlinde amavalve ukuncipha ukugcina.

Imigomo Yokubuya Amasele Ukuze Kuvikele Leak

Shintshe amasele uma ubone leak noma ukulawula manzi. Khalse ukuphazimba kwehydraulic, hlamba amathanki wamanzi, bheka amasele ngamathizinu akuyiqa. Manzi anezinkomba eziningi ayadinga ukubuyekezwa ngokwesine, okunciphisa amathambo ka 40%.

Isimo Somanzi Sokulinganisa Imicimbi Yemachine Yamanzi

Ukujabulisa Ukujabuliswa Kwesistimu Yokulula Ukuze Kuvikele Amabheiringi Eppump

62% ye bearing failures isuka kwehlonywa (le ngaphezulu kuka-100 ppm TDS). Sebenzisa ukulula okuhlanganisiwe:

- Izinhlukwana zokulula ngeminyaka

- Ukubuya komembrani we reverse osmosis ngeminyaka enguvesi

- Izinhlukwana zika-Micron ngaphambi kokucindezela amandla

Linda TDS ngezansi kuka-50 ppm ukuze uthintele izindleko zebhiringi ngo-40%.

izindlela Zokwenza pH Ngokulinganisa Ukuvikela KweCorrosion

Linda ipH phakathi kuka-6.8-7.5 ngoku sebenzisa imininingo yokugcina ngokuzenzekela. Ibhese enobukhosi (>120 ppm calcium) idinga izinkinobho ukuze uvikele ukushaya. Ukuvavanya ipH ngeminyaka ungene ekuthinteleni kwe-corrosion failures ngo-75%.

Izindlela Eningiyo Yokugcina Uhlelo Oluphakeme Oluphakeme

Izindlela Zokubhalwa Kwamagajini Wezinkinga

Izingxenye zezinkinga eziphezulu kuka±5% ziyabonisa ukungabi lula. Izinhlelo zaseNyanja zethu (-IoT-enabled systems) zivavanya izinto ukuze bethole ukuphazimba kwepompi kuqala. Ngokwesibongo saHigh-Pressure Systems Report 2025, izinsensa ezinhle prevent 38% yezindlalifa eziphakeme futhi engavunyelwanga ukungabi nokuxhuma.

Ukuvikela Imishakelo Eningi Ngokusebenzisa Ukuhlulahlula Kwe-Flow Rate

Izindlela ezingaphansi kwe-3.8 GPM kumaqondana amaningi angu-60Kpsi ngamathuba ukuphakama okanye ukucima komthwalo. Sebenzisa:

- Ukuh сравna izindlela zokukhipha ngehlobo

- Izilarmu zokuya phambili kweengu-15% engavunyelwa

- Ukusungwa kwesibili

Ukuyinqanisa ukukhipha nokugcina isitresi kudala amathuba osebenziswa ngokuwa ngu-27% futhi kuneke kube yide.

Ukusebenzela Imigomo Yokuqinisa Isimfanelo

Izisanti zasevisi ezijwayelekile zikuthula amasiphi ngama-41% futhi zenze kube yide ngama-27%.

imibhalografa ye-Inspection Checklists Yezinto Eziningi Kwiminyaka Engu-30/60/90

- iminyaka engu-30 : Bheka amasele aphakathi nevalve

- 60-izinsuku : Velela umkhawulo wokwenza (±2% yemiphumela engavamile)

- 90-izinsuku : Bheka imihose yesayensi nezindlela zokulula

Lesi sapho lula ukuba kube khona izisinda ezingathathelwa ngemva kwezinyezi ezingu-23%.

Ukuphepha kwesistimu yokukhipha ukulula ukuze kube nephephandaba elijwayelekile

- Ukubhekwa kwesikhwama sehopelo ngoweke

- Ukuthola futhi ukulula kokulula (1.2-1.8 lb/min) ngawebele

- Shintsela imitjwengubo yokuhanjiswa noma kunezibani elikhulu kunesiphumo esingu-0.5mm

Ukuphepha okungcono kulula ukushintsha komkhawulo wezinhlangothi ngemuva kwezinyezi ezingu-34% kanye nokul stabilise umkhawulo wesayensi (85-95 psi).

Imibuzo Evame Ukubuzwa

Yini engqimba ukuphunzwa nokuvukela kwe nozzle emashini yamanzi?

Ukuphunzwa kwe nozzle kungenhla ngamanzi anemindleke nezindlovu zokwenza ububanzi be nozzle, noma kuvukeka ngokuthi kungcinwe ngamanzi aphelileyo abonisa ukuncipha fokwengceke.

Yini engqimba ukususa izindleke zokucindezela kwi nozzle?

Iindlela eziphambeneyo zokucima njenge ukulula manzi ematholeni, usebenzisa ukucima ngokudlala komoya oluhleli kwi mixing chambers, kunye nokucima amagama esibhedlelo ngamathuluzi atholileyo okutya we-nylon kuyindlela efanelekileyo.

Yintoni i-recommended frequency yokutshintsha i-waterjet orifices?

Kuyindlela efanelekileyo ukutshintsha i-orifice ngaloo ndlela ngaphandle kwe 80-120 iintsuku zokusebenza, hhayi xa lokhu kuhluka ngokwesiko kunye nemigca ekusebenzekayo.

Yintoni eyenzeka ngokuba kakhulu kumgangatho wamanzi kumanzi asebenzisa iindlela zokusebenza?

Imanzini embalwa iyenza ukuba kube liphuma kwe 62% kwabantu abasebenzisa i-bearing, ngoko ke ukucima phakathi kwezinye Iindlela kunye nokulandelela kwe-pH kuyinto enkulu ukuze ikhankatha inqanawa.

Uhlu Lwezinto Eziqukethwe

- Izimpendulo eziphambene neyohlunga weNozzle

- Izindlela Zokucula Ezilandelayo Ukususa Izicelo zeAbrasive

- Ukulinganisa izilingo ne-analisi yokunciphisa izindleko

- Ukugcina Imijet Yebhombu kwemijet Sistimu Yokukhupha

- Isimo Somanzi Sokulinganisa Imicimbi Yemachine Yamanzi

- Izindlela Eningiyo Yokugcina Uhlelo Oluphakeme Oluphakeme

- Ukusebenzela Imigomo Yokuqinisa Isimfanelo

- Imibuzo Evame Ukubuzwa