- Core components: PLC, motor, Gearbox, Pressure vessel, Gear, Pump

- Warranty: 1 Year

- Weight (kg): 3000

- Place of origin: Jiangsu, China

- Repeatability (x/y/z) (mm): ±0.025

- Table travel (x) (mm): 3000

- Table travel (y) (mm): 1500

- Table travel (z) (mm): 200

- Number of axes: 3

- Video outgoing-inspection: Provided

Key attributes

Industry-specific attributes

| Core components | PLC, motor, Gearbox, Pressure vessel, Gear, Pump | Warranty | 1 Year |

| Weight (kg) | 3000 | Place of origin | Jiangsu, China |

| Repeatability (x/y/z) (mm) | ±0.025 | Table travel (x) (mm) | 3000 |

| Table travel (y) (mm) | 1500 | Table travel (z) (mm) | 200 |

| Number of axes | 3 | Video outgoing-inspection | Provided |

| Machinery test report | Provided | Cutting accuracy(mm) | ±0.1 |

| Brand name | YuanChuang | Dimension(l*w*h) | according to machine model |

| Key selling points | Long Service Life | Name | Water jet cutting table of water jet cutting machine cutter |

| Cutting materials | stone ,plastic ,Stainless steel , brass, aluminum, glass.etc | Cutting accuracy | +/-0.1mm |

| Max.flowrate | 3.7 L/Min | Drive system | AC servo and screw ,guiderail |

| Size | Custom-made | Structure | Gantry or cantilever |

| Colour | White and red or custom-made | Working pressure | 320-400mpa |

| Abrasive name | Garnet |

Packaging and delivery

| Selling Units: | Single item |

| Single package size: | 500X400X500 cm |

| Single gross weight: | 4000.000 kg |

Product descriptions from the supplier

Product Description

CNC Water Jet Cutting Machine Parameter(L=Gantry type) | |||||||

Parameters |

Unit |

CY-L1010 |

CY-L2015 |

CY-L3015 |

CY-L3020 |

CY-L2060 |

|

Efficient Cutting Area |

mm |

1000×1000 |

2000×1500 |

3000×1500 |

3000×2000 |

2000×6000 |

|

Axis Travel |

X |

mm |

1000 |

2000 |

3000 |

3000 |

2000 |

Y |

mm |

1000 |

1500 |

1500 |

2000 |

6000 |

|

Z |

mm |

150-180 |

150-180 |

150-180 |

150-180 |

150-180 |

|

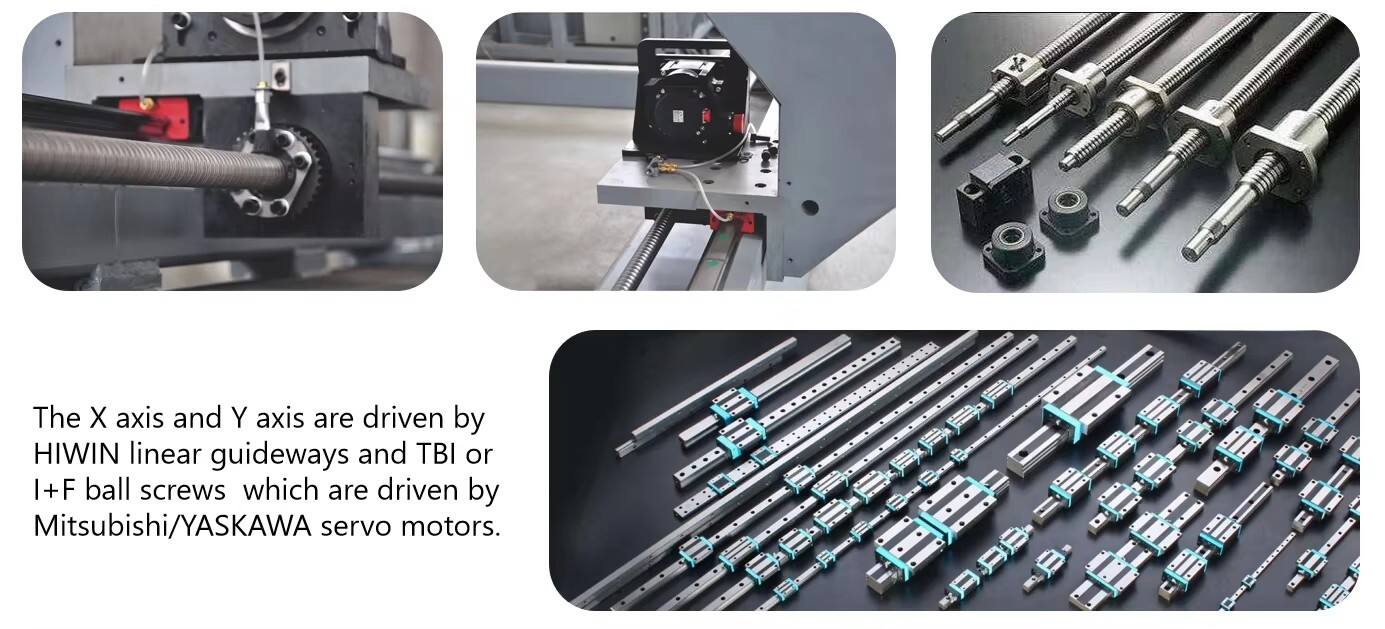

X axis and Y axis adopt HIWIN or I+F ball screw and guideway;The servo motor to drive we adopt MITSUBISHI or Yaskawa | |||||||

Cutting Accuracy |

mm |

±0.1 |

|||||

Positioning Accuracy |

mm |

±0.025 |

|||||

X,Y Dry-run Speed |

m/min |

0-15 (if need 30m/min speed,we can do as request ) |

|||||

Cutting Speed |

m/min |

as to detail material and thickness |

|||||

As an advanced cutting equipment, the water jet cutting machine has a wide range of applications in the industrial field. A

complete set of water jet cutting machines usually consists of five main parts: the first is the high-pressure system, which is the key to generating high-pressure water flow and provides strong power support for cutting; the second is the cutting platform, which bears the material to be cut and provides a stable foundation for the cutting operation; the third is the control system, just like the intelligent center of the equipment, accurately regulating various parameters of the entire cutting process; the fourth is the cooling system, which effectively reduces the temperature during the operation of the equipment to ensure the stability and safety of the equipment. The cooling system includes air-cooling system and water-cooling system, and it is necessary to reasonably choose the equipment with high or low cooling intensity according to different usage temperature environments to adapt to the specific working condition requirements; the fifth is the sand supply system, which plays an important role when abrasive water jet cutting is required to ensure the smooth supply of abrasives. The sand we use is generally 80-mesh garnet sand, which has good cutting performance and stability.

How is our CY waterjet cutting platform made?

Waterjet cutting head

Ultra-high pressure water jet is mainly divided into abrasive cutting and only water cutting(Including pure water cutting).

Therefore, the cutting head is also divided into abrasive waterjet cutting head and pure waterjet cutting head.

* Abrasive waterjet cutting is mainly used for cutting metal (such as carbon steel, stainless steel, etc.), nonferrous metal

(such as copper, aluminum, titanium alloy, magnesium alloy, etc.), stone, glass, large thickness composite materials (such as carbon fiber, glass fiber) and so on.

* Only water cutting is mainly used for cutting rubber, foam, cloth, paper, rock wool, food (pure waterjet cutting)and so on.

What materials can a waterjet cut?

Alloys,Steels,Laminates,Composites,Plastics/Acrylics,Rubber,Gaskets,Fiberglass,Glass ...

Customizable Waterjet Cutting Systems

| Customizable X, Y, and Z axesMachine tool with a z-axis of 1 meter | Customized model of tube plate integrated water cutting machine | Customization of water cutting production line |

Company Profile

Taizhou Chuang Yuan Machine Tool Co., Ltd. is located in Hailing Industry Park Taizhou City, Jiangsu Province, China, with a number of research and development and manufacturing bases. Our company specializes in researching,manufacturing and selling precision machines.Taizhou Chuang Yuan Machine Tool Co., Ltd. has built long term and close cooperation relationships with many foreign friends, covering more than 20 countries, and we are looking forward to more cooperations with friends from all over the world, and hope our products could help more friends in their local industry and business market development. Our company established in 2003, has 96 employs, and sold about 200 sets about the machines all of the world. We always keep our enterprise mission---“Quality changes the world” in mind. We start our work from each trivial matter, and do our best to complete each detail well, and offer solid technical service and good service to our machine customers.Quality guarantee, high efficiency, valuing friendship, observing credibility and sincerity-oriented” is our enterprise principle,which all staff should abide by. Quality and honesty are the keys of the enterprise future.

TCK50A-800 Cnc 5 Axis Custom Machining Combination Lathe Milling Machine for Metal Mould Making

Cnc Water Jet Cut Water Cutting Machine 5 Axis High Pressure Water Jet Cutting Machine

China Manufacture Machining Center VML1160 Machining Center Two Lines and One Hard 5 Axis Machining Center

Wholesale High Quality Numerical Control CNC Die Sinker Machine Znc Sinking Machine Znc350