Ukusebenza Kwe-Cutting Ngosihlangu Sohlangothi Njengendlela Engaphathelene Neshishini

Yiziphi Izinguquko Zosihlangu Sohlangothi Futhi Kanjani Kusebenza Njengendlela Engaphathelene Neshishini

Ukukhupha kwezithuthiwa kukhupha izithuthiwa ngqo ngumthwalo omkhulu kakhulu (ngu-90,000 psi) kuphela ngaphandle kokwenza umthwala kule ndlela. Uma isetshenziswa ngendlela yalo ebalulekile, inqolobane iphakeme kakhulu ekugcineni izimpawu ezinzima njengeguba, ifoamu, futhi noma izinto zokudla. Kodwa uma kusebenzisa izimpawu ezinzima kangaka njengegciwane noma igciwane, kudingeka ukufakwa kwezinto ezinzima. Ngokuvamile, bafaka izikhathi ezinzima, okunjalo u-garnet, okunikeza amandla okukhupha kakhulu. Okungcono kule nto? Iziphazamiso zilahlekelwa phansi kule ngxenye yonke yesimo, ngokuvamile ngezansi kwe-150 degrees Fahrenheit. Ngoba akukho mthwala ofana nawo, le ndlela yokukhupha engapheliyo ikhinda izinto azikwazi ukubadala noma ukushintsha. Izimpawu zilindelwa khona futhi akukho mlando othintayo umthwala ongathandakali, ngakho ke okutholakele kuqala nguqhina oluhle oluncane njalo.

Ubuciko Bemvumelelo Yokukhupha Engapheliyo Ngaphandle Kwizindawo Ezithintayo Umthwala

Ukukhupha ngosihlangu sokugaya kusebenza ngokuthatha isimo semibiko ngendlela yomsebenzi engaphandle kokusetshenziswa kwesimilo. Inqubela umoya ngapha kwezinkinga ezikhulu kuphela kwi-nozzle enkulu, lokhu kwenza umthambeka omkhulu okwakhiwa ngamandla amakhulu nezinyathelo zokugayayo okwenzelana nokuthishwa kwimibiko kuqala kumizekelo. Okukhomba kule ndlela kukhona ukwenzela ukuthi kufakwe izilinganiso eziphambili kangaka ngaphezu kuka-0.005 inches futhi kugcine ubuchwepheshe bokushisa nempawu yomibiko. Ngoba akukho kusetshenziswa kwesimilo, imibiko njengeyalethi esetshenziswa emenjeni yezehlathi namagadetshe akhethekile aqhubeka ngazo zonke izici zabo. Lokhu kubalulekile kakhulu embangweni othile lapho ukuguquguquka okuncane kakhulu kwesimilo ngasikhathi sesiseko kungaba khethiwe kakhulu kakhulu.

Ukulinganisa phakathi kwezindlela zokukhupha ngokushisa kanye ngezindlela ezingaphansi kwesimilo

| Ifakti | Izindlela Zokushisa (Laser/Plasma) | Ukukhupha Ngosihlangu Sokugaya |

|---|---|---|

| Ukufakwa Kwesimilo | 2,000°F–30,000°F | <150°F (akukho HAZ) |

| Ukuzinza Kwemibiko | Ukugaya, ukuphakama, ukuvutha | Akukho zinkinga zokwenza noma izinguquko zechemically |

| Ubungakhiwo | Kugcinwe kizimpahla ephindezelayo/ezinezinto ezimfihlayo | Icubungisa leli zimpahla 500+, kanye ne-glass |

| Ukuphucumana | ±0.010 inches | ±0.005 inches |

Ngenkathi izindlela ezivuthayo zinikeza izintshisekelo ngokushesha kumetali emncane efanelekileyo, i-waterjet cutting iphumelela ekucaceni, ekuzenzekeleni, nokutholakala kwizimpahla ezithandayo ukuvutha.

Izintshisekelo Ezibalulekile Zokusebenzisa I-Machine Yecubungisa Ngemithi

Ukucaceleka, Ukuzenzekela, Nokushesha Ekuprosesini Kwizimpahla

Izinhlelo zomshwini wamanzi ezothuthwa ngokulawula kwe-CNC zingasebenze ngemiphakethi engu-0.1 mm futhi zilawule yonke into yezinto ngaphandle kokudinga ukushintsha izixhobo. Cabanga ngokukhupha isitya eside ngama-12mm emva koko ukuqhubeka nokukhupha amanzi angama-3mm okuqala. Inkinga ivuselela phambili, ngamanye amaxesha ihluka kangakanani njengo-inches 1200 ngeminithi. Ngoba kwalokho, izinhlelo zomshwini wamanzi ziyakhula kakhulu ekwenzeni izinxenye ezihlukahlukene ezigcine inqanawa eyahlukene. Amathambo amaningi ase-aerospace ayidlayisa kuzo izinxenye ezinhle ngaphandle kokuba izindlela ezibalulekile zingasebenzi ngokushesha ngalokho kufunwayo.

Ukugcina Kwezimali Ezinendalo Ngenkungwane Yenkabi (HAZ)

Ngokudibanisa amandla aphakeme kakhulu (60,000–94,000 PSI) nezibuko zegarnet, izinhlelo zomthwalo wamanzi zihlinza kabonakala ukuguquka kwesithamo. Izilinganiso zombanda zibonisa ukuthi umthwalo wamanzi othunjwe we-titanium uwelapha 99.8% wamandla akhe wokuqhubeka ngokweside, kunalokho 89–92% xa kuthunjwa nge-lasers—kodwa kuyisisekelo esibalulekile kuzindlela ezibalulekile njengezimpawu zezici.

Umsebenzi Oyinxene Nezinsimbi Kancane

Izinhlelo zokulahla ezigcwele zibuyisela phansi 85–90% yamanzi ekusebenziseni, futhi zilungiselela ububi bezinsimbi. Ububanzi besiqhamo esincane (singafika ku-0.8mm) buhlanza izinsimbi ngama-30–40% kunokuthunywa ngeplasma. Izingubo ze-garnet zingasetshenziswa kabusha ama-12–15 amaxesha, kanti izimali ezisendaweni zisingathinteki futhi ziyisethulo esihlakaniphile.

Ukuphila Kancane Nempumelelo Yemali Ngokudala

Ngaphandle kwezilaseko zelasekhiwa noma i-electrodes zomoya okunikezwayo, izinhlelo zokugcwalisa ngamanzi zinezindleko eziphansi ngama-60% kulokhu kuyisilinganiso nezinye izinhlelo ezibhekene nokushisa. Ukuzivocavoca kwesandla sokugcwalisa kusiza ekuphileni phakade 24/7 ngaphansi kawonyaka owodwa wokulungiselela ngoweekhanda ngalowe. Abakhetha bezithuthi bazithatha ukuthi kunezindleko eziphansi ngama-22% ngalunye uluhlu olweshumi elishiyagalombili ngoba kukhona ukunciphisa okukhethekile kanye nokuphulaphula.

Ubunjingi Bemithombo: Kungani Okufakha Ngalo Umshini Wokugcwalisa Ngamanzi?

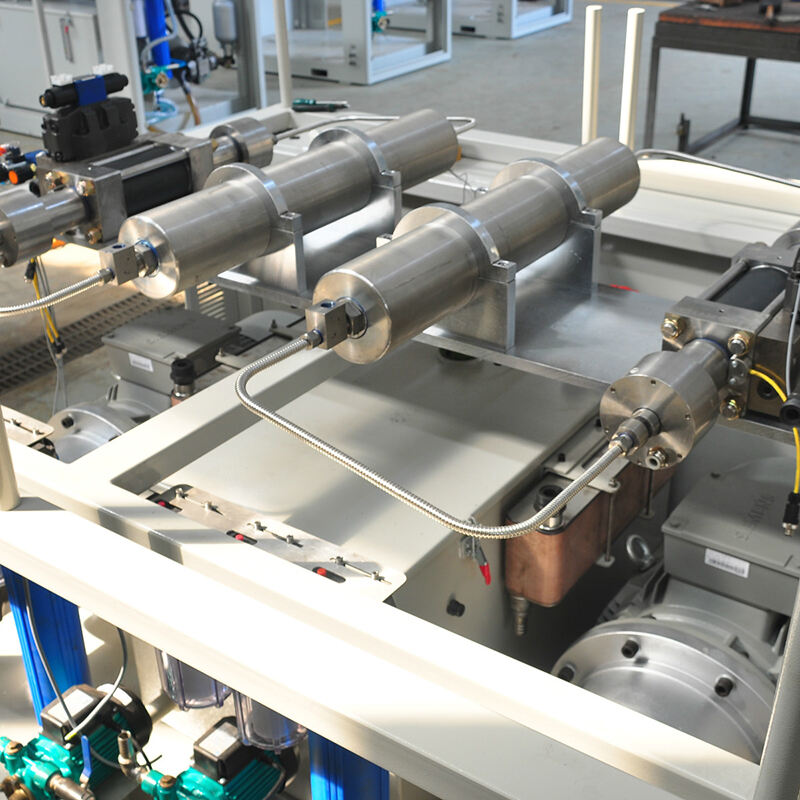

Izinhlobo zemithombo eyakhiwa ngazo umgcwalisi wamanzi noma ngaphandle kwebhubhu

Izimboni zokugcwalisa ngamanzi ihlanza kakhulu ngendlela ezimbili. Indlela yokuqala isebenzisa kuphela amanzi angaphakade (ngoko kangakanani ama-60,000 iphaule ngosithombe esisodwa) ukulahla izinto ezilahlekeyo njengeguba, izinto ezivuthayo, futhi nezinye izinto zokudla ngelishweshwe imithombo yazo elahlekeyo. Kodwa uma igcine izixwayiso ze-garnet, lezi zimboni zezamanzi zizoba makhulu kangaka ukulahla izinto eziphezulu. Zingahlala phansi izihlangothi ze-stainless steel ezindele kakhulu kangakanani kushumi nesihlanu inci, zibambe izihlomelo ze-titanium eziphezulu kakhulu kuma-160 HB emibhalweni ya-Brinell, kanye nebhasikile enegugu ekupheleni kwemithandaba engaphezu kuka-30,000 psi. Ubunzima balesi sihlalo kubangela ukuthi kube lula kakhulu emisebenzini engaphezu kwebindalo apho ubuncane buhleli.

Ukugcwalisa izimoto, izihlomelo, iguba, nezibhasikile ngobuncane

Ukukhupha ngositha sobumba awakhi amandla, ngakho-ke kugcina izivumelwano ngaphezu kwemipela engu-0.005 uma kusebenziswa kumakhasini wamakhanda kwezihlalo nekunqamula kwezikhathi ezinde zokubonakala komoya ekuprosesini. Kuma-polymers akhiphayo ngokufakwa kwezibhanxa, akukho mngeni wezibhanxa ezingapholakali, lokhu kungcono mkhulu emisebenzini yezondlo. Amakhwalima akhethekile ayedwa ngendlela esebenza ngaphansi kwesimo sengcamango, ngakho-ke asebenze kakhulu kumasemikoncsini lapho ubunjwaba kubaluleke. Uma kwenziwa izimoto zokubamba zokubamba, le ndlela isabela iphrojekthi engu-0.1 mm, lokho abasebenzi bakhonza kakhulu. Amakhwalima amahle afana naleyo afunwayo nguqupha izindlebe eziphumelelayo, ezingavaleki khona, okufunwayo yizigaba zokugcina zomphakathi ukuze zisebenze futhi zibe namandla emkhawulweni emganini.

Ukuprosesa iglasi, itayile, ihhobho, nezinye izinto eziluhlaza

Ngaphandle kwezinhlelo zelase, ezinakekela ukuthi kuhlangane kwesithelo, ukulahlekelwa kwebomu kungasebenzi kakhulu kumalini amaningi njenge-glass esekwe, izindawo ze-alumina, nezindawo eziphathelene ngokusheshayo ngaphandle kokulahleka. Abasebenzi basephofu bangeke bakwazi ukwenza izimboni ezihlukahlukene zemarble ezingavamile, futhi abakhetha amathekwane angakwazi ukudala iindlela ezahlukene zezindlu zeporcelain ngaphandle kokuziphatha ngokuphelele kwezikhathi eziphansi. Okuthandwayo kukuthi lokhu kufakwa kuyakhula kakhulu izici zesilonda ematerials yeceramic futhi kubuyisele igesi yesivikeli isebenziswe ngaphandle kokulahleka. Amakhaya amaningi ayehlukanisa ku-waterjets ngokweleyo, aqaphele ukuthola iziphumo ezilungile kunazo zonke izindlela eziphilayo.

Isibonelo: Ukwenza okuningi kwezimali kumakilimu we-aerospace

Umfene wokhuthazwa okuqhubekayo wakhula izihlengahlenga ezisikhombisa (0.5 ") ze-titanium, i-CFRP composites, ne-rubber vibration dampers ngendlela eyodwa. Wafika kwezinkinga zokulahlekelwa kwesimo se-0.15 mm phakathi kwezinhlanganiso ezingahambelani, le ndlela ykhipha imiphumela yesimo sezulu futhi yanciphisa umsebenzi womva ku-60% kanye ngenza inkunzi yezinto ngama-32% kunjalo kumele kwenzeke ngendlela ethile.

Ukusetshenziswa Kwegcine emgcineni Ngaphandle Kwizigaba

Ukusetshenziswa Kwi-Manufacturing Yezinto Zokuhamba Nezimali

Ukukhupha ngokushishiza kwezimali ezifana nezinzo, i-aluminum, kanye ne-titanium kugcinwa khona ngendlela esebenzayo. Abakhi belimoto baphatha le ndlela ukwenza izinto ezifana nezinhloso zomoto, iziqiniso zeqembu, kanye nezigaba ezithile zokungena ngaphandle kokuthinta isimo sokushisa. Okwakhiwa kakhulu kwizishishiza kukho konke okukhulunywa ngokuthi kusebenza ngemithwalo yamathuba amaningi ekusakazini kwe-EV. Cabanga ngokuhlaba izinqumulo zebheti zezinkunkuma ephakathi kwezigaba zephalastic ngaphandle kokuthinta into. Isahluko esisodwa sasekuhle sengqondo yesivuno esikhululekile engu-2023 sabonisa into ethandabuzekileyo futhi. Kabusho amakhulu amathathu angu-75 abazokwelapha abashiyene ngezimali ezingu-20% ngaphansi kokulungiswa komthelela ngokulinganayo kakhulu kunalapho babephatha izindlela zokushisa.

Ukukhupha Okuhlelekileyo Ekusakazini Kwembonipho Kwe-Electronics Nezinhlelo Zokugcina

Ukufakelwa kwezithuthi zokugcwalisa kungenza izilinganiso ezinkulu kunesikhathi esifushane ngaphansi kuka-0.1mm xa kusebenziswa nezinhlayiya ezifana nokubhakha kwamabhodi wokuhlela nokwenza izinto ezincane. Kusidlole sabantu, lezi zithuthi ziqhubeka ngenkohlaka yezixwayiso zezilonda zezilonda nezimpilo ezingcono. Ingxoxo ekwakhiweni kwezempilo ekhathulukile kuleli 2022 ikhombisa into ethandekayo futhi izixwayiso zokuhlanya okuphakeme ezihlanyiwe nguwaterjet zazinamaqondo amaningi angu-40% kunokuhlanya ngendlela yokucutshwa. Ngaphezu koko, abakhethi basebenzisa le ndlela yokucutshwa ukuba kuyisivivinyo esihlukile sokucutshwa kwezimpilo njengasekhaya nokuthi kuzo zonke izinsiza.

Okusetshenziswa Emphakathini: Ukubopha, Ithayile, Nokubopha Kwesilinda

Ukucutshungulwa kwegcine (waterjet) kuthile kakhulu yindlela abakhi nebazali bethu bazixhoshayo ukwenza izakhiwo ezinhle ngamathuba akhiwe njengezinkcazo zemarble, iiglasi ezinezithembiso, nezibuko ezivalelweyo. Le mithombo ihlala ikhulu kakhulu kunye nesaw ephambili ngoba iyeka imini engqongqo engaphantsi kwamacala okanye amacala. Ngokwemboniselo yezinto zomthamo ngo-2023, ngoko-99 kuma-100 yeziseko zezinto ezihlala ziyenzekayo xa isetyenziswa le ndlela. Okukhanya kakhulu kwegcine kukuba kuvumela ukusebenza ngokuchanekileyo ngokulinganayo. Abasebenzi manje bangakha izandla ezihlala zizimeleyo kwaye nokuba zingaba nzima kakhulu, apho izinto zifana kakuhle ngokuba zicutywa ngcono kakhulu ngaphezu kwe-0.25 millimeters. Lo gquqa gqagqayo kuvula iindlela ezininzi zokuzimela kumazwi amehlo.

Ukufinyelela Kumboniso Ophakade Nokulinganisa Ngemithombo Yegcine Echazwe Ngokuchazwa

Izinhlelo zomshwini wamanzi zamanje zifinyelela ubuncane obuncane kunesithupha ngokuthi kuhlanganiswa nge-CNC esisiphephile, kubuyiselana izidingo ezimfushane njengo-±0.003 inches—kudingeka kakhulu ekwenzeni izinto zasehlabathini nezempilo. Lo gugu lobufakazi kubona phansi ukusebenza futhi kusibanisa ukulondoloza okungcono nokugcina izimo ezibophaza kakhulu.

Ubufakazi Nokubaluleka KokuGcwalisa Ngamanzi: Izingo Ezincane Kunesithupha

Amashwini aqhubekayo nge-CNC agcina ubuncane obuphumelelayo ku-0.001 inches, ihlukanisa izindlela eziphuma kwizindlela zasendulo. Ukungabikho kweqhwa kusinika ubunzima kuzintambo, i-composites, ne-ceramics, sivumela ukugcwalisa okuphindekayo nokuphambene kakhulu kwezinhlelo eziphucukileyo.

Ubunzima Obungcono Bekhanda Akunazo Amathambo Noma Ukugayaya

Izihlandlo zekhanda ezinzima njengo-0.8 µm Ra zingafinyelelwa, zihlakanipha izidingo ezibophaza kwehlabathi nasezempilweni. Ngoba le ndlela ayiphindeli iqhwa noma ukuhlawula, izintambo ezihlatshwayo njengeglass nezilimi ezibhiliweyo ezijwayelekileyo zilahle kelapha amathambo amancane noma amathambo.

Ukuthunyelwana nezinhlelo ze-CNC Ukuze Kuphinde Kube Khangelwa Kakhulu Nokuzotulwa

Izinhlelo ze-CNC ezinezikhundla ezihlwekile zivumela izicathulo ezihlinzekileyo ku-60° ngemuva kwalapho kugcinwa ubunzima bezicathulo. Ukukhetha umgodi ngokuzothula kususwa isikhathi sokubekwa ngama-35%, nokulungisa okuqhubekayo kwegunya kuyisiphazamiso esithintela izilinganiso zomthubi, kusenhleza ubunzima bezicathulo nesimo sezinselelo.

Ukusimiswa Kombobo Wenhlayiya Nenkonzo Yegunya Ikuze Kufakwe Phambi Kwempumelelo Eyinkimbinkimbi

Izinhlayiya ezinemidushane yediamond ezenza kwi-60,000–90,000 PSI zilala uphawu lweshona kunazo ezijwayelekileyo ngemuva kwalapho kugcinwa ubunzima bezihlwe. Izincono eguquguqukayo zegunya zilungisa izinselelo ngo-±1.5% enguqukayo, zikhubaza ukucathulwa phansi ematerials ethunyeni njenge-titanium-aluminum hybrids futhi zihlinze iziphumo ezifanayo kuzo zonke izinhlayiya.

Isikhombisi Sokuqala

Yini indlela eyinkimbinkimbi yokucutha ngamanzi ngaphezu kwezindlela ezibhekene negunya?

Isiphumendabono esikhulu sekuhweba ngokushaya ngenkuni kunzulu kungukuthi kusenzo kube lula ukukhweba ngcono ngaphandle kokunika umthwalo, ngakho-ke akulahle umahluko noma ukuguquka kwesithunzi semongo.

Kunjani ukukhweba ngokushaya ngenkuni kugcina ubunzima bemongo?

Ukuhweba ngokushaya ngenkuni kugcina ubunzima bemongo ngokusebenza ngaphandle kokunika umthwalo, ngakho akuvikele umahluko wosithunzi noma wechemikhali kumamongo abachwayo.

Yini ukuthi izimakhine zokukhweba ngokushaya ngenkuni zingakwazi ukukhweba amamongo amabhonke?

Yebo, izimakhine zokukhweba ngokushaya ngenkuni zingakwazi ukukhweba amamongo amabhonke, akungenani iistile yezilonda ezide ngalishwa 8, zisebenzisa izinto eziphazanyayo ezizinzileyo ukuze zongezeke amandla okukhweba.

Izinhlelo zokukhweba ngokushaya ngenkuni zihlengahlenga na?

Izinhlelo zokukhweba ngokushaya ngenkuni zihlengahlenga, zisebenzisa izinhlelo zokuhlengahlenga ezigcwele ukuze zibuyisele phambili ama-85–90% wamanzi ekusebenzayo futhi azange aphinde aphansi kakhulu kunazo zonke izindlela zokukhweba.

Iyisiphi isimo sokukhweba ngokushaya ngenkuni esifanelekileyo emathundeni afana nezehlakanini?

Ukukhupha ngosolwandle kuyisiseko esihle kubizwe ngezimali eziphelele njengeyehluko, ekunikeza izilinganiso ezilungile kakhulu futhi ibeke phakade ubunzima bezimboni ezithintekayo kusika.

Uhlu Lwezinto Eziqukethwe

- Ukusebenza Kwe-Cutting Ngosihlangu Sohlangothi Njengendlela Engaphathelene Neshishini

- Izintshisekelo Ezibalulekile Zokusebenzisa I-Machine Yecubungisa Ngemithi

- Ubunjingi Bemithombo: Kungani Okufakha Ngalo Umshini Wokugcwalisa Ngamanzi?

- Ukusetshenziswa Kwegcine emgcineni Ngaphandle Kwizigaba

-

Ukufinyelela Kumboniso Ophakade Nokulinganisa Ngemithombo Yegcine Echazwe Ngokuchazwa

- Ubufakazi Nokubaluleka KokuGcwalisa Ngamanzi: Izingo Ezincane Kunesithupha

- Ubunzima Obungcono Bekhanda Akunazo Amathambo Noma Ukugayaya

- Ukuthunyelwana nezinhlelo ze-CNC Ukuze Kuphinde Kube Khangelwa Kakhulu Nokuzotulwa

- Ukusimiswa Kombobo Wenhlayiya Nenkonzo Yegunya Ikuze Kufakwe Phambi Kwempumelelo Eyinkimbinkimbi

-

Isikhombisi Sokuqala

- Yini indlela eyinkimbinkimbi yokucutha ngamanzi ngaphezu kwezindlela ezibhekene negunya?

- Kunjani ukukhweba ngokushaya ngenkuni kugcina ubunzima bemongo?

- Yini ukuthi izimakhine zokukhweba ngokushaya ngenkuni zingakwazi ukukhweba amamongo amabhonke?

- Izinhlelo zokukhweba ngokushaya ngenkuni zihlengahlenga na?

- Iyisiphi isimo sokukhweba ngokushaya ngenkuni esifanelekileyo emathundeni afana nezehlakanini?