Common Causes of Nozzle Erosion and Clogging

There are 2 main causes of nozzle wear – erosion from water containing minerals (>100ppm total dissolved solids) and sand particles –, widening the diameter of the nozzle, and disruption of jet precision. Clogging only compounds the problem when spent garnet abrasive or debris from the workpiece block flow channels. Combined, these drives result in erratic kerf widths and taper cuts, weakening or failing machining accuracy up to 70% prior to its demise (20024 Flow Science). Regular inspection after every 50 cutting hours allows detecting deformations early.

Optimal Cleaning Techniques for Abrasive Particle Removal

Prevent irreversible damage with systematic purging:

- Flush waterjet lines with distilled water for 5 minutes

- Use ultrasonic cleaning for disassembled mixing chambers

- Clean orifice interiors with nylon-tipped tools only

Maintain water pH levels between 6-8, as acidic or alkaline fluids accelerate corrosion. Centrifugal filtration captures 97% of sub-50-micron particles, significantly extending nozzle lifespan when used preemptively.

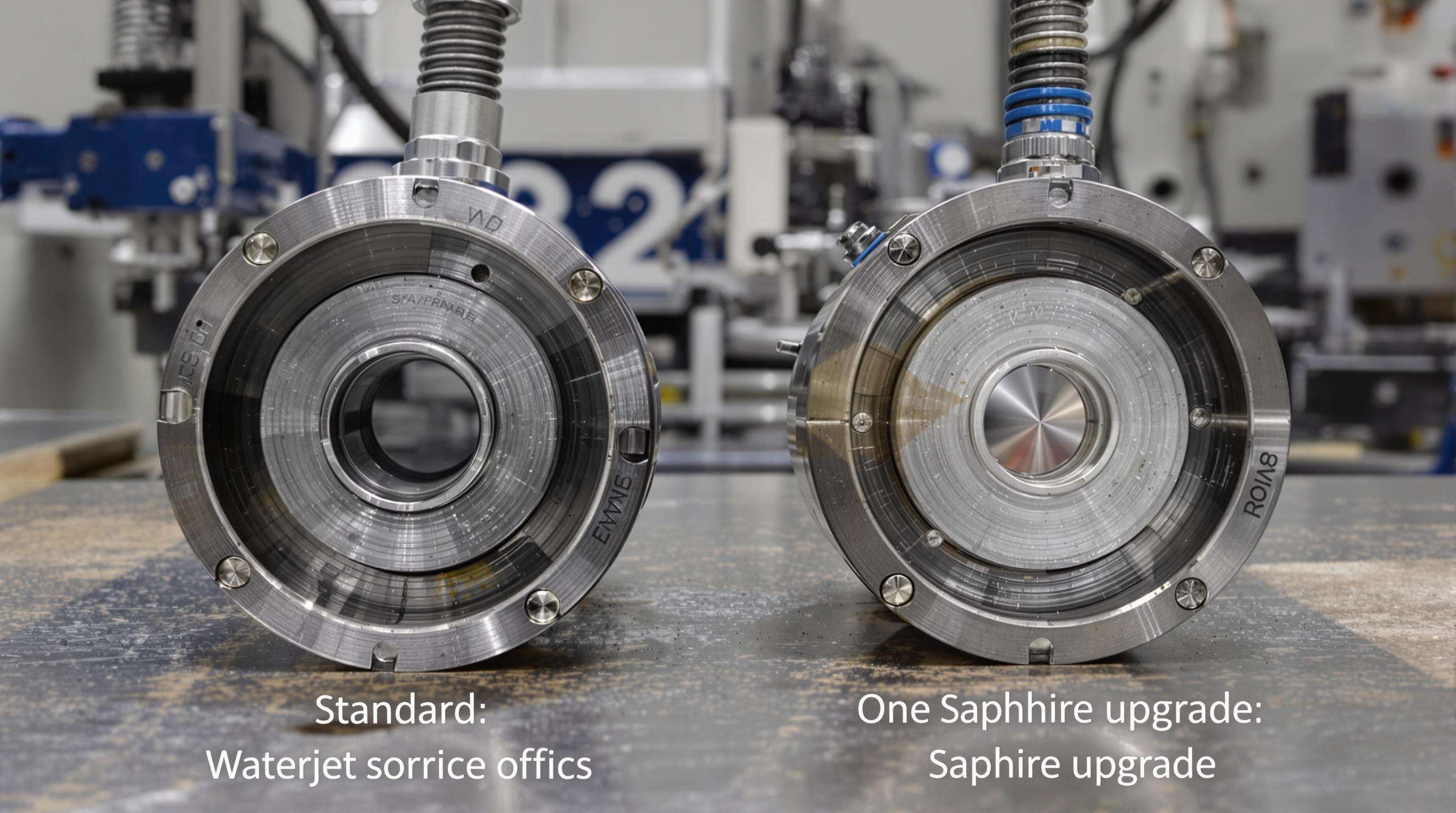

Orifice Replacement Frequency and Cost-Efficiency Analysis

| Factor | Standard Orifice | Sapphire Upgrade |

|---|---|---|

| Avg. Lifespan | 100 hours | 400 hours |

| Cutting Speed Retention | -55%/150 hrs | -12%/400 hrs |

| Annual Savings Potential | Baseline | ~$5,300* |

*Based on 24/5 operations plus downtime costs (Industrial Waterjet Association 2023). Recalibrate within 2 hours post-replacement to maintain jet cohesion—delayed adjustments waste up to 18% of abrasives. Track degradation against material types to optimize replacement intervals (typically 80-120 cutting hours for efficiency).

Diagnosing Pump Failures in Waterjet Cutting Systems

Hydraulic Pressure Fluctuations: Testing and Calibration Methods

Irregular pressure affects cut quality and causes audible surges. Test static pressure when components are cool, allowing for ±5% deviation from specifications. During cutting, use diagnostic software to monitor ripple patterns. Annual recalibration prevents drift.

Identifying Overstroking Through System Performance Data

Overstroking strains bearings and intensifier rods, indicated by high oil temperatures (>68°C) and abnormal stroke frequency. Analyze performance logs for mid-stroke instability. Optimize water pressure and inspect check valves to reduce pulsation.

Seal Replacement Protocols for Leak Prevention

Replace seals upon detecting leaks or oil contamination. Isolate hydraulic pressure, bleed water systems, and extract seals with non-marring tools. High-hardness water requires quarterly checks, reducing part costs by 40%.

Water Quality's Impact on Waterjet Cutting Machine Components

Filtration System Maintenance to Protect Pump Bearings

62% of bearing failures stem from contaminated water (>100 ppm TDS). Use multi-stage filtration:

- Weekly sediment filters

- Quarterly reverse osmosis membrane replacement

- Micron filters before cooling circuits

Keep TDS below 50 ppm to cut bearing costs by 40%.

pH Balancing Strategies for Component Corrosion Prevention

Maintain pH between 6.8-7.5 with automated monitoring. Hard water (>120 ppm calcium) requires softeners to prevent scale. Weekly pH testing reduces corrosion failures by 75%.

High-Pressure System Monitoring Best Practices

Real-Time Pressure Gauge Interpretation Techniques

Pressure deviations >±5% signal potential failures. IoT-enabled systems analyze trends to detect pump wear early. According to the 2025 High-Pressure Systems Report, smart sensors prevent 38% of catastrophic failures from undetected instability.

Preventing Catastrophic Failures Through Flow Rate Analysis

Flow rates below 3.8 GPM in 60Kpsi systems often indicate blockages or seal wear. Implement:

- Weekly flow rate comparisons

- Alerts for >15% variance

- Thermal compensation

Combining flow and pressure monitoring cuts maintenance costs by 27% and extends component life.

Implementing Preventive Maintenance Routines

Standardized maintenance schedules reduce delays by 41% and extend component lifespan by 27%.

30/60/90-Day Inspection Checklists for Critical Components

- 30-day: Check pump seals and valve clearances

- 60-day: Test intensifier pressure (±2% tolerance)

- 90-day: Inspect hydraulic hoses and abrasive lines

This approach reduces unscheduled repairs by 23%.

Abrasive Delivery System Maintenance for Consistent Performance

- Weekly hopper screen checks

- Bi-monthly abrasive flow verification (1.2-1.8 lb/min)

- Replace accelerator tubes with >0.5mm diameter increase

Proper maintenance reduces nozzle replacements by 34% and stabilizes pneumatic line pressure (85-95 psi).

FAQ

What causes nozzle erosion and clogging in waterjet machines?

Nozzle erosion is primarily caused by water with minerals and sand particles that widen the nozzle's diameter, while clogging is exacerbated by spent garnet abrasive and debris blocking flow channels.

How can abrasive particles be removed from nozzles effectively?

Systematic purging techniques such as flushing waterjet lines, using ultrasonic cleaning for mixing chambers, and cleaning orifice interiors with nylon-tipped tools are recommended.

What is the recommended frequency for replacing waterjet orifices?

Orifice replacement is typically recommended every 80-120 cutting hours, although this varies based on use and materials being cut.

How does water quality affect waterjet cutting machine components?

Contaminated water leads to 62% of bearing failures, hence, multi-stage filtration and pH balancing are crucial to maintaining component integrity.

Table of Contents

- Common Causes of Nozzle Erosion and Clogging

- Optimal Cleaning Techniques for Abrasive Particle Removal

- Orifice Replacement Frequency and Cost-Efficiency Analysis

- Diagnosing Pump Failures in Waterjet Cutting Systems

- Water Quality's Impact on Waterjet Cutting Machine Components

- High-Pressure System Monitoring Best Practices

- Implementing Preventive Maintenance Routines

- FAQ